Luxury Vinyl Tile, also known as LVT, is a relatively new product to the flooring industry, but its popularity is growing – and quickly.

With nearly 50 years in the flooring industry we know a good thing when we see it. We know what discerning modern clients like quality and resilience, value, style and options.

When we think about the resilience of flooring products available today, LVT flooring is specifically manufactured to be more resistant to dings and dents, scratches and moisture damage when compared to real wood flooring. At the same time, LVT Flooring will provide an authentic design aesthetic too.

Talk about the best of both worlds!

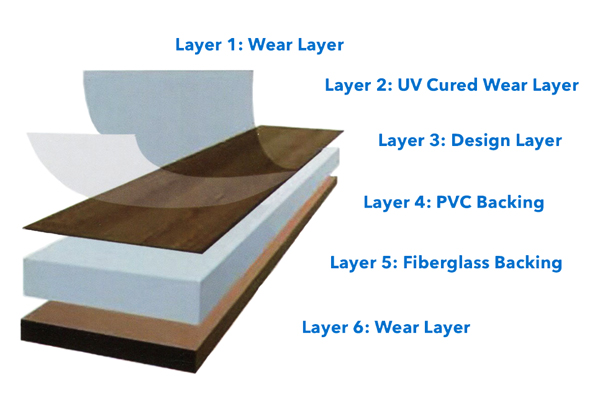

Let’s take a closer look at the construction of luxury vinyl tile flooring to understand the different layers that are involved in creating this flooring sensation:

Layer 1: Wear Layer – The top layer of your LVT Flooring is a transparent wear layer. This layer will come into contact with foot traffic and protects the flooring from wear and tear and liquid contact from spills or weather. Ideally, you want to make sure your LVT Flooring is finished with a quality urethane that offers great protection, but is also easy to clean and maintain.

Layer 2: UV Cured Wear Layer – The UV Cured Wear Layer offers additional protection to the vinyl design layer. The wear layer for LVT Flooring varies depending on manufacturer. The thicker the wear layer the better. Like engineered flooring and laminate flooring, LVT flooring cannot be sanded or refinished so the thicker the wear layer is the longer the flooring may last. Thickness is measured in millimeters. We recommend that your consult your flooring suppliers to confirm this, information on the product warranty and to make sure you receive care and maintenance guidelines to keep your floor looking beautiful.

Layer 3: Design Layer – The design layer of the LVT flooring provides the image that will set the design for the flooring. Like laminate flooring, LVT is meant to replicate hard surface flooring materials such as stone, wood or tile using a realistic photographic image. This image is impregnated under a clear UV cured vinyl layer which lends itself to a more authentic appearance with more natural colors and texture.

Layer 4-6: Multiple layers of PVC and Fiberglass Backing – This layer provides the stability and supportive backing for installation. This is the part of the flooring that will be used for installation. As with all flooring, the installation methods used for installing LVT flooring varies depending on the type of flooring, installation conditions and subfloor conditions. LVT flooring can be installed floating or glue down, some are available with click & lock system, which can make installation easier and reduce installation time.

When it comes to quality, there are a variety of LVT flooring manufacturers today, and it pays to do your homework, to make sure you are asking the right questions and getting the right product for your project.

Luxury Vinyl Tile flooring offers clients fabulous flooring solutions in a variety of colors, styles and looks, often at a fraction of the price of real wood floors. While real wood flooring will always have a place in our heart, and our showrooms, we know that there are budget conscious consumers and commercial projects where the consistent look, durability and cost makes LVT Flooring a better fit.